SILCOR® 1100

Single layer, cold, spray-applied for building deck and basement wall waterproofing Membrane

Description

SILCOR® 1100 is a tough while flexible, seamless, fast and easy to apply structural waterproofing membrane designed for buried application and the protection of concrete structures based on GCP’s (previously Stirling Lloyd) unique ESSELAC® advanced resin technology and extensive experience in the development of coatings for specialist waterproofing. SILCOR® 1100 enables fast return to service and provides long term protection and peace of mind for the building owner.

Benefits and values

- Faster, Easier, Tougher, Safer and Long Lasting

- Cold applied

- Applied in single layer

- Applied all year round: Unaffected by high humidity & high temperature, no sensitivity to Relative Humidity, can be applied up to 99% RH

- Quick curing even at low temperatures; allows wet film thickness measurement ensures quality

- Unlimited overcoat time: No critical overcoating time on any coat or lap reduces waste, saves cost, saves time and enables schedule flexibility

- Tougher: Robust but flexible, Site trafficked within one hour to allow other activities

- Highly portable, mobile and easy to use cost effective cold applied spray machine; no hot works or heated hoses

- Durable: high adhesion to concrete reduces effect of accidental damage

- Chemical, abrasion, UV and weather resistant

- Excellent dynamic and static crack bridging capability

- No root barrier requirement for green roof and landscaped podium gardens

- High bond strength to substrate

- Can be applied to 14 days old concrete, tensile adhesion of surface should pass >0.7MPa

- No weak day joint: Simple, easy and seamless detailing; No cutting or jointing, no weak seams and easily repairable

- On site Quality Assurance checks: No destructive thickness test; Wet film thickness measurement and electronic pin hole checks

- Standard membrane can be hand applied; contact GCP technical services for details

- SILCOR® 1100 membrane is low VOC as defined by the EU Directive 2004/42/EC and the VOC Globe label categories (British Coatings Federation)

- This product does not contain any ozone depleting substances according to the EU Ozone Depleting Substances (ODS) Regulations 1005/2009/EC.

Uses

SILCOR® 1100 is designed to protect structures from water.

SILCOR® 1100 Spray Grade is suitable for larger areas and can achieve outputs of 3,000m2 per day dependent on site conditions.

For SILCOR® 1100 Hand Grade application which is ideal for application in small areas or where restricted access prevents spray application; kindly contact your GCP representative for an application guideline.

Typical applications include:

- Podium Decks including Green and Bio-Diverse landscaping

- Basement retaining walls

- Balconies

- Roofs - including Green and Bio-Diverse roofs

- Concrete, masonry, suitable asphalt* or steel substrates requiring a chemical and/or abrasion resistant coating

- Sewage and sludge tanks

- Contact your local GCP representative for further details on suitable asphalt substrate

| Application Temperature Range | |

| Standard Grade Tropical Grade |

0°C to +30°C 15°C to 50°C |

| Typical Overcoating Time | 60 Minutes |

Surface Preparation

All surface coating systems are dependent on the quality of surface preparation.

Concrete

New concrete substrates should be a minimum of fourteen days old and constructed in accordance with BS EN 1992. The substrate must be clean, dry and structurally sound. It must be free from laitance, oils and all other surface contaminants. Where the use of a non-structural screed or a lightweight concrete substrate is proposed, contact Technical Services as these materials often have low cohesive strength or retain water in open pores. Please refer CSP (Concrete Surface Profile) by ICRI (International Concrete Repair Institute) for additional guidance on acceptable surface preparation.

Steel

On steel surfaces all rust, dirt and contamination should be removed to expose bright metal to achieve a surface finish to receive suitable metal deck primer. For compatibility with other construction materials or where additives, cement replacement or curing compounds have been used please consult the GCP Technical Services Department.

Application

Primer

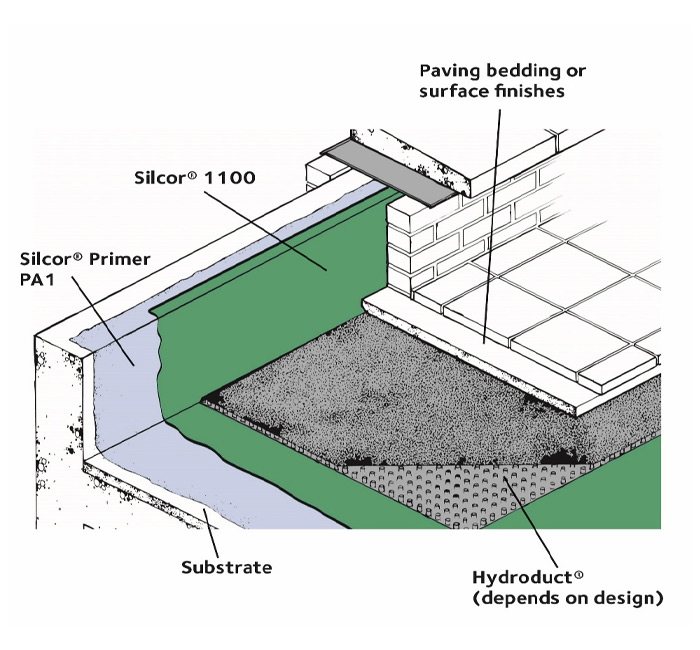

The substrate must be primed with an appropriate GCP primer prior to application of the SILCOR® 1100 membrane. A choice of primers is available depending on the type of substrate and weather conditions. They are usually applied using a brush or roller. Please consult the appropriate datasheets of Primer PA1 for concrete surfaces and refer to datasheets of Primer ZEDS 94 for Metal deck.

Membrane

SILCOR® 1100 is applied in one single coat.

SILCOR® 1100 can be applied using spray and hand, kindly contact GCP Technical Service for application guideline.

SILCOR® 1100 Spray Grade is spray-applied in 1.7mm Wet Film Thickness to give a minimum dry film thickness of 1.5mm. The coverage rate will vary with surface texture. It is highly recommended to use Wet Film Thickness gauge to measure the wet film thickness continuously. Please refer to SILCOR® 1100 application guideline for further details.

SILCOR® 1100 can be foot trafficked or loaded once fully cured.

SILCOR® 1100 can be connected and fully compatible with GCP PREPRUFE® Pre-applied membranes. SILCOR® 1100 will require a protection layer against backfill when used on vertical retaining wall Kindly contact GCP Technical Services for a connection detail and backfill recomendation.

SILCOR® 1100 will require a protection or separation layer depending upon design of final finishes when used on horizontal decks, please contact GCP Technical Services for further details.

Coverage

| Primer | Refer to separate datasheet |

| Membrane (Spray) | Typically 1.9kg/m2 |

Coverage rates are based on a smooth substrate and will vary with surface texture and porosity.

Cleaning

All tools and equipment should be cleaned with acetone before the material is allowed to cure.

Packaging & Storage

| Primer PA1 | 20 Kg pails & 190 Kg drums |

| 48 Kg KIT size | 400 Kg KIT size | |||

| Pail size | Pails/pallet | Drum size | Drums /pallet | |

| SILCOR® 1100 Part A | 24 Kg | 12 | 200 Kg | 2 |

| SILCOR® 1100 Part B | 23.04 Kg | 12 | 192 Kg | 2 |

| BPO Powder Catalyst | 960 g | * | 8 Kg | * |

All components of the SILCOR® 1100 system should be stored in cool, dry, protected conditions, out of direct sunlight and in accordance with the relevant site Health & Safety regulations. Storage temperature must not exceed 25°C. Do not store near naked flames or foodstuffs.

Stored in unopened containers, under the correct conditions, the components have a minimum shelf life of twelve months. If your product is more than twelve months old you must contact GCP Technical Service before use.

*BPO Powder Catalyst’ is classified under H242 Hazard, UN Number ‘UN3106’, ADR, IMDG, IATA, requires special shipping, cannot be shipped together with any other material in a container and comes under 1000Kg maximum loading restriction per container.

Ancillaries

GCP produces a range of products to compliment the SILCOR® 1100 system. These include:

- METASET® – a range of ESSELAC® resin based rapid curing levelling and repair compounds.

- MMA Reinforcement Scrim – available in 1160mm and 180mm width for construction joint reinforcement.

- Contact GCP Technical services for further information.

Typical Properties

| PROPERTY | TYPICAL VALUE | TEST METHOD |

| Wet film thickness | 1.7mm | Wet film Gauge |

| Dry film thickness | 1.5mm | |

| Colour | Chrome Green | |

| Coverage, 1.7mm WFT | 1.9Kg/m2 | |

| Density of cured membrane | 1.1g/cm3 | ASTM D 792 |

| Trafficable (foot traffic time), 23 degree C | 30 mins | |

| Typical Curing time, 23 degree C | 15 mins | |

| Tensile adhesion Strength of membrane, MPa | Concrete Substrate >0.7 Steel Substrate >2 PVC Substrate >2 |

BS EN ISO 46241 ASTM D 7234 |

| Intercoat overlap adhesion after 7 days without surface preparation | Same as tensile adhesion of membrane to the surface | BS EN ISO 4624 |

| Tensile strength, film | 12MPa | ASTM D4122 |

| Elongation, film | >130% | ASTM D412 |

| Puncture resistance | 600N | ASTM E 154 |

| Impact resistance | 600mm | EN 12391 |

| Resistance to Hydrostatic Head | Pass at 70m | ASTM D 5385 |

| Dynamic Crack bridging @ 0 degree C | 2mm | ASTM C 1305 |

| Static crack bridging @ 0 degree C | >2mm | BS EN ISO 4624 |

| Water vapor transmission | 0.5 Perms | ASTM E 96 |

| Water Absorption | 2% | ASTM D 570 |

| Shore A Hardness | +90 | ASTM D 2240 |

| Shore D Hardness | +50 | ASTM D 2240 |

2. Typical Value subject to +/- 10% tolerance

Health and Safety

Safety and Handling - Read and understand the product label and Safety Data Sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements. SDSs can be obtained by contacting your local GCP representative or office.

General Information

SILCOR® 1100 is part of a wide range of specialist waterproofing materials manufactured and supplied by GCP. If you require any further information on this or any other of our products, please do not hesitate to contact us or visit www.gcpat.com.

ESSELAC® - Special Polymer Technology

- SILCOR® 1100 offers a unique combination of characteristics to meet customer needs

- A unique formulation that determines the performance of the product

- Developed and manufactured in house

- Over 40 years GCP have perfected several unique ESSELAC® polymer resins, each lends specific characteristics to the final product to tailor performance for the demands of a particular application.

gcpat.in | India customer service: +91 124 4885900

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the end user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with out conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

SILCOR® 1100 and METASET® are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been complied using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2020 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA

GCP Applied Technologies India Private Limited, Unit No. 208, Second Floor, Time Tower Building, Sector-28, MG Road, Gurugram, Haryana-122002, India

This document is only current as of the last updated date stated below and is valid only for use in India. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.in. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-15

https://gcpat.in/en-gb/solutions/products/silcor-1100-liquid-waterproofing/silcor-1100